How Is The Manufacturing Industry Evolving As A Result Of Digital Transformation That You Should Know

No other industry has experienced the transformations that digital transformation is bringing to the manufacturing business since the turn of the millennium. This transformation can only be called a revolution, the Fourth Industrial Revolution! Ford automobiles were mass-produced during the first industrial revolution. The product being mass-produced in this situation is information and data.

However, like with every revolution, strategy is the key to success. The war is underway, and participation is no longer optional! So what is digital transformation, and how should businesses use it to their advantage? Here’s all you need to know:

-

Transformation to the Result Of Digital Transformation

The force that is transforming the planet is transformation. Your smartphone’s processor is more powerful than the first rocket ships that landed on the moon. Switching from manual to automated processes and leveraging data insights to make business decisions is what digital transformation entails. The cloud, big data, and other transformative technologies enable this change digital transformation.

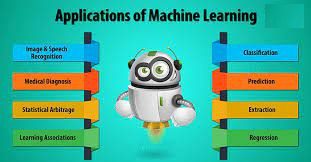

Artificial Intelligence (AI), Machine Learning (ML), and the Internet of Things (IoT) are three terms that are used interchangeably (IoT). At every level of the production process, these technologies enable communication between business divisions. Many CIOs are concerned that their companies are falling behind their competition, including new start-ups that pop up every day.

- The Fourth Industrial Revolution is a period of rapid technological advancement.

“Poverty is the father of revolution,” declared Aristotle digital transformation. This is not the case with the Fourth Industrial Revolution! Downtimes, accidents, waste, fraud, and errors are all caused by inefficient industrial processes. Current factories are unable to adapt to changing client expectations. They are unable to anticipate emerging trends or simplify their supply networks.

Customers no longer demand mass-produced things due to the Fourth Industrial Revolution. Instead, your clients seek personalized items that are made using innovative technology. 86 percent of businesses are undergoing digital transformation. Supply chain, product development, customer service, and agile manufacturing are part of the Fourth Industrial Revolution. The key is to use sensors to link data to people and systems.

Every second of the day, employees and company operations must be monitored. This is required for the factory to understand what it needs to simplify procedures. Anything that cannot adjust must be destroyed as soon as possible since it will only obstruct the intelligent factory’s ability to achieve this fourth revolutionary shift.

more like this, just click on: https://24x7offshoring.com/blog/

Only a personal revolution within your company may start the process digital transformation. The revolution’s goal is to simplify, and your company must be engaged in streamlining as a goal in and of itself. Companies must be prepared to flourish in a future where orders of magnitude reduce overhead, operational, and capital expenses—a world where production timeframes are orders of magnitude faster.

- Manufacturing using Intelligence

Integrating data analytics, machine learning, IoT, big data, and AI into the production process is known as smart manufacturing. Smart manufacturing aims to expedite the production process digital transformation, identify problems before they occur, and satisfy consumer expectations in previously unimaginable ways.

Employees leverage this technology to generate faster product cycles, offer customized goods, learn more about their customers, and enhance their supply chain. Machine learning can evaluate purchase patterns and identify supply chain flaws before they become a problem.

Data analytics, CRM, ERP, and cloud computing are all part of today’s smart factory. Predictive analytics increases employee safety while lowering expenses. Sensors can use these insights to notify factories before they break down digital transformation.

These intelligent sensors allow for more agile processes with less downtime. These gadgets would have been too big and expensive to wind up on a production floor before the Internet of Things. Instead, these are now needed for a professional manufacturing process, thanks to the Internet of Things development.

This factory is focused on the needs of its customers. New goods are produced and planned based on analytics discovered in purchase and search patterns. Within a shipping time, an outdated style might be updated and reused digital transformation. In addition, the companies might change their logos or designs to correspond to current events in the news or on social media.

Using this data to forecast patterns automatically allows for more responsive decisions. For example, if data shows that consumer demand will vary quickly, demand projections help determine the best production speed.

- How to Take Advantage of the Situation

“Failure to explain competitive value distinction” is the leading cause of client loss for digital businesses. This indicates that, despite the most significant efforts of the company, clients are unable to comprehend the services accessible to them digital transformation.

Sales and marketing departments cannot adapt to digital models at the pace required in today’s industry. Employees need access to the data created by their intelligent technologies to make decisions that will drive development and keep them competitive in the market.

Companies must be prepared to provide customized solutions as well as hyper-specialized products. If businesses don’t have these alternatives, the internet’s worldwide expansion will force their customers to turn elsewhere digital transformation. Your factory’s most valuable asset is information.

- How do you pick the right team?

These insights are millions of times better than any person at predicting safety, consumer demands, machine output, or supply chain links. It’ll all come down to the software engineer team you hire. They will be the most valuable employee in your firm. Hundreds of product managers can be replaced with the skills of a single AI developer. You’ll need a group that’s honest, dependable, and fair, as well as a leader in their sector digital transformation.

Employees may resist because they are afraid of becoming automated, although this is untrue. The competition, not automation, is the real threat. Your ability to automate quickly will determine whether or not your firm survives.

Continue Reading: https://24x7offshoring.com/blog/

mass-produced in this situation is information and data: https://en.wikipedia.org/wiki/Information

transformative technologies: https://transformativetechnologies.org/

inefficient industrial processes: https://nrtcautomation.com/blog/5-reasons-your-production-line-is-inefficient

identify supply chain flaws: https://www.riverlogic.com/blog/the-biggest-supply-chain-challenges-of-2020

drive development: https://www.drivedevelopment.com/

firm survives: https://www.mckinsey.com/featured-insights/future-of-work/from-surviving-to-thriving-reimagining-the-post-covid-19-return

How Is The Manufacturing Industry Evolving As A Result Of Digital Transformation That You Should Know

No other industry has experienced the transformations that digital transformation is bringing to the manufacturing business since the turn of the millennium. This transformation can only be called a revolution, the Fourth Industrial Revolution! Ford automobiles were mass-produced during the first industrial revolution. The product being mass-produced in this situation is information and data.

However, like with every revolution, strategy is the key to success. The war is underway, and participation is no longer optional! So what is digital transformation, and how should businesses use it to their advantage? Here’s all you need to know:

- Transformation to the digital age

The force that is transforming the planet is transformation. Your smartphone’s processor is more powerful than the first rocket ships that landed on the moon. Switching from manual to automated processes and leveraging data insights to make business decisions is what digital transformation entails. The cloud, big data, and other transformative technologies enable this change digital transformation.

Artificial Intelligence (AI), Machine Learning (ML), and the Internet of Things (IoT) are three terms that are used interchangeably (IoT). At every level of the production process, these technologies enable communication between business divisions. Many CIOs are concerned that their companies are falling behind their competition, including new start-ups that pop up every day.

- The Fourth Industrial Revolution is a period of rapid technological advancement.

“Poverty is the father of revolution,” declared Aristotle digital transformation. This is not the case with the Fourth Industrial Revolution! Downtimes, accidents, waste, fraud, and errors are all caused by inefficient industrial processes. Current factories are unable to adapt to changing client expectations. They are unable to anticipate emerging trends or simplify their supply networks.

Customers no longer demand mass-produced things due to the Fourth Industrial Revolution. Instead, your clients seek personalized items that are made using innovative technology. 86 percent of businesses are undergoing digital transformation. Supply chain, product development, customer service, and agile manufacturing are part of the Fourth Industrial Revolution. The key is to use sensors to link data to people and systems.

Every second of the day, employees and company operations must be monitored. This is required for the factory to understand what it needs to simplify procedures. Anything that cannot adjust must be destroyed as soon as possible since it will only obstruct the intelligent factory’s ability to achieve this fourth revolutionary shift Result Of Digital Transformation

more like this, just click on: https://24x7offshoring.com/blog/

Only a personal revolution within your company may start the process digital transformation. The revolution’s goal is to simplify, and your company must be engaged in streamlining as a goal in and of itself. Companies must be prepared to flourish in a future where orders of magnitude reduce overhead, operational, and capital expenses—a world where production timeframes are orders of magnitude faster.

- Manufacturing using Intelligence

Integrating data analytics, machine learning, IoT, big data, and AI into the production process is known as smart manufacturing. Smart manufacturing aims to expedite the production process digital transformation, identify problems before they occur, and satisfy consumer expectations in previously unimaginable ways.

Employees leverage this technology to generate faster product cycles, offer customized goods, learn more about their customers, and enhance their supply chain. Machine learning can evaluate purchase patterns and identify supply chain flaws before they become a problem Result Of Digital Transformation

Data analytics, CRM, ERP, and cloud computing are all part of today’s smart factory. Predictive analytics increases employee safety while lowering expenses. Sensors can use these insights to notify factories before they break down digital transformation.

These intelligent sensors allow for more agile processes with less downtime. These gadgets would have been too big and expensive to wind up on a production floor before the Internet of Things. Instead, these are now needed for a professional manufacturing process, thanks to the Internet of Things development.

This factory is focused on the needs of its customers. New goods are produced and planned based on analytics discovered in purchase and search patterns. Within a shipping time, an outdated style might be updated and reused digital transformation. In addition, the companies might change their logos or designs to correspond to current events in the news or on social media.

Using this data to forecast patterns automatically allows for more responsive decisions. For example, if data shows that consumer demand will vary quickly, demand projections help determine the best production speed.

- How to Take Advantage of the Situation

“Failure to explain competitive value distinction” is the leading cause of client loss for digital businesses. This indicates that, despite the most significant efforts of the company, clients are unable to comprehend the services accessible to them digital transformation.

Sales and marketing departments cannot adapt to digital models at the pace required in today’s industry. Employees need access to the data created by their intelligent technologies to make decisions that will drive development and keep them competitive in the market.

Companies must be prepared to provide customized solutions as well as hyper-specialized products. If businesses don’t have these alternatives, the internet’s worldwide expansion will force their customers to turn elsewhere digital transformation. Your factory’s most valuable asset is information Result Of Digital Transformation

- How do you pick the right team?

These insights are millions of times better than any person at predicting safety, consumer demands, machine output, or supply chain links. It’ll all come down to the software engineer team you hire. They will be the most valuable employee in your firm. Hundreds of product managers can be replaced with the skills of a single AI developer. You’ll need a group that’s honest, dependable, and fair, as well as a leader in their sector digital transformation.

Employees may resist because they are afraid of becoming automated, although this is untrue. The competition, not automation, is the real threat. Your ability to automate quickly will determine whether or not your firm survives.

Continue Reading: https://24x7offshoring.com/blog/