Custom solution for your data?

The data you rely on Custom is different from your company. And you have different questions that you would like to have answered. Install AI Assembler, a toolkit for building machine learning solutions focused on different native language problems.

Speed up and do it automatically, Assembler Forum helps you speed up and automate the process of data management, analysis and predicting size orders. AI Assembler saves time and reduces costs by simplifying tasks such as hyper-parameter function optimization, data set adjustment, and more.

Start small, small risk

Do not spend large sums on a tool that fails to deliver. The AI Assembler lets you start small with a low-risk program that answers a few, small questions. Verify your results, verify your ROI, and expand its capabilities.

Use immediately

AI Assembler machine learning models are easily integrated into Analytics ’local or cloud-based natural language processing solutions. In addition, all Assembler interactions come with the full support of our ML Builders expert team

“What does AI need from you?”

As people of color, women, the disabled, LGBTQ +, and other vulnerable communities are equally affected by data-based technologies, we must find practical ways to incorporate them into the creation, training, and testing of algorithmic matrices that we measure now and will continue. to do so in the future with ever-increasing consequences.

These systems are marked by the same bias that is responsible for the system injustice we face today. We can no longer be idle consumers or people who ignore the algorithmic systems that greatly affect how we live and where we live, our loved ones and our ability to build and distribute wealth.

Launched by Stephanie Dinkins in 2017 as a conference in NEW INC, a New York-based art and technology incubator at the New Museum, AI.Assembly is now underway at the Data & Society Research Institute as a series of close-knit, exploratory research. These circles create space for sidelined practice and thinking about smart systems where we can think about what AI needs from us and what we want from it. They also work to plant seeds and transfer pollen to a broader contribution to ethics, equality, transparency, and innovation in machine learning and techno culture.

The relationship between human and machine learning has entered a new phase. The ever-growing power of computers, combined with almost unlimited data, has led to a shift in the skills of artificial intelligence. Wise artificial intelligence systems quickly penetrate our public and personal lives; the need to evaluate the effects of human interactive robot (AI) is more important than ever.

Four AI.Assembly workshops were held at NEW INC (NY) and MOOGFest (Durham NC) from September 2016 – August 2017. AI.Assemble dinner with 20 artists, researchers and color professionals and partners working in and around the area. AI surroundings. was held at the Data & Society on November 29, 2018. AI.Assembly conference is in the process of Fall 2019.

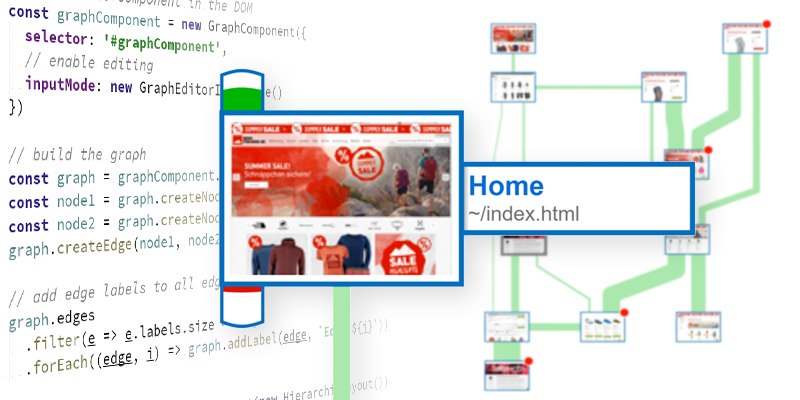

Artificial Intelligence on the Meeting Line Custom

The machine learning feature highlights units that appear to have a feature. Photo Credit: Instrumental, The machine learning feature highlights units that appear to have a feature. Photo Credit: Instrumental

When Anna-Katrina Shedletsky worked as an engineer at Apple, she often found herself traveling overseas and spending weeks in a factory to fix a problem with a mechanical welding machine. Finding the root of the problem can be like finding a needle in a haystack. It is a process that analyzes the most personal failures that can cause significant scheduling delays.

Also, when it comes to product production, time is money. Not to mention the small window of opportunity once the product reaches the market. For example, Apple AirPods wireless earbuds were shipped a few months after the release of the iPhone 7, which did not have a headphone jack. An expensive problem — and somewhat embarrassing.

Fortunately, Anna, who was the product design leader for the Apple Watch, was not part of the AirPods debate. And, in fact, he was not part of Apple at all at the time; he was busy launching his business creating a system that would help power companies recognize and fix integration problems very quickly. Based on his experience with colleagues who spend hundreds of days working for producers responsible for Apple’s multi-million dollar products, he and his team have a deep understanding of the inefficiencies of the new product development process — and the value of not moving away from home. . To do that, a product designed by Shedletsky can analyze confusing distances online.

Shedletsky is the founder and CEO of Instrumental. Launched in May 2015, California start-up $ 10.3 million backed by Eclipse Ventures, First Round Capital and Root Ventures. The difference here is that the hardware / software product uses machine learning to diagnose problems quickly.

The system includes test channels and software tools that allow developers to remotely review images of any unit, while dismantling the device to understand what went wrong, take measurements, contact a global team, and make specific changes or alterations to stop delays. they start.

Here’s how it works: First, test systems take multiple product images while in the integration line. Then, make those images searchable and comparable. And, lastly, it works by reading and responding to compound line data so that engineers can prevent further problems.

The machine learning feature, called “Find” and launched this month, highlights units that appear to be flawed, giving customers a significant threshold for solving product problems.

“Detect uses Convolutional Neural Networks, a machine-learning method, processing hundreds of units and identifying the most interesting units that need to be reviewed in seconds,” Shedletsky said. “The detective does not need to foresee what might go wrong, no training, and no gold parts. Works on both small and large data sets. ”

When used in combination with other hardware software tools, an engineer can diagnose the problem and take the next step by almost dividing the units and taking measurements to understand what is wrong. These are the tools to analyze long-distance failures that are much needed to save valuable time and communication between companies and the companies that make their products.

Also, while the Instrumental Detect automatically scans hundreds of units and identifies the most interesting problems in seconds, the company will soon begin to alert engineers directly when it detects intriguing units.

Get all your business need here only | Top Offshoring Service provider. (24x7offshoring.com)